MyHelmet

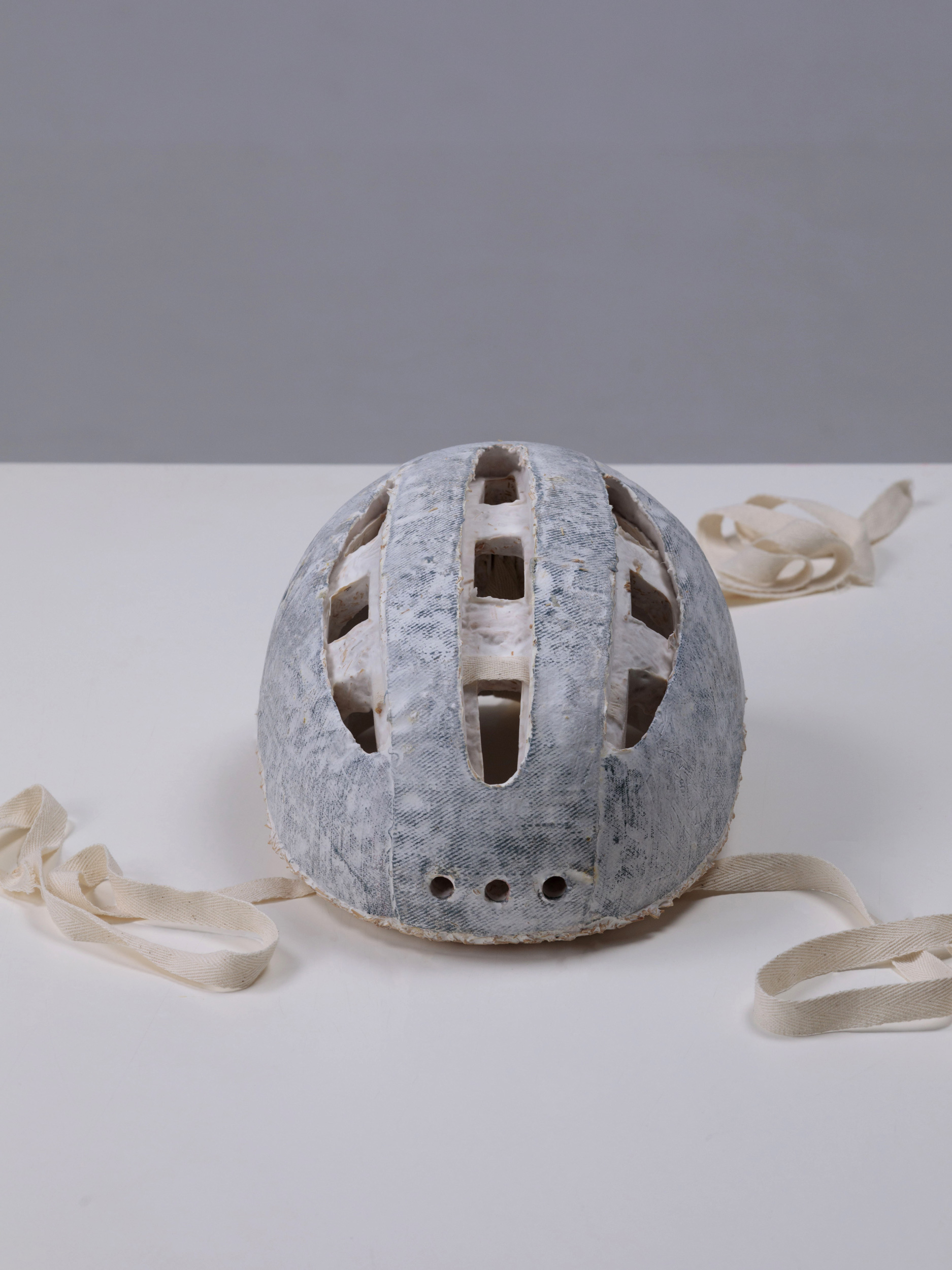

Safe for your head, good for the environment. StudioMOM’s industrial designers turned a ‘normal’ bicycle helmet into a game changer. MyHelmet fits in with principles of the circular economy: there are minimal CO2 emissions, it does not require any fossil raw materials and the end result is 100% biodegradable.

The following description is courtesy of the designers. For safety reasons, you have to replace a bicycle helmet every 3 years. This creates a waste stream of a hard-to-recycle, glued together mixture of foam and plastic. StudioMOM wondered if it would be possible to develop a helmet that is less harmful to our planet?

Replacing EPS with mycelium and hemp flakes

The Arnhem based design studio had already been experimenting with bio-manufacturing based on mycelium and hemp flakes for some time. Mycelium is the root network of a fungus that feeds on the flakes. Briefly heating this mixture stops the growth process, resulting in a material with properties similar to EPS, the harmful foam in conventional bicycle helmets.

A challenging puzzle

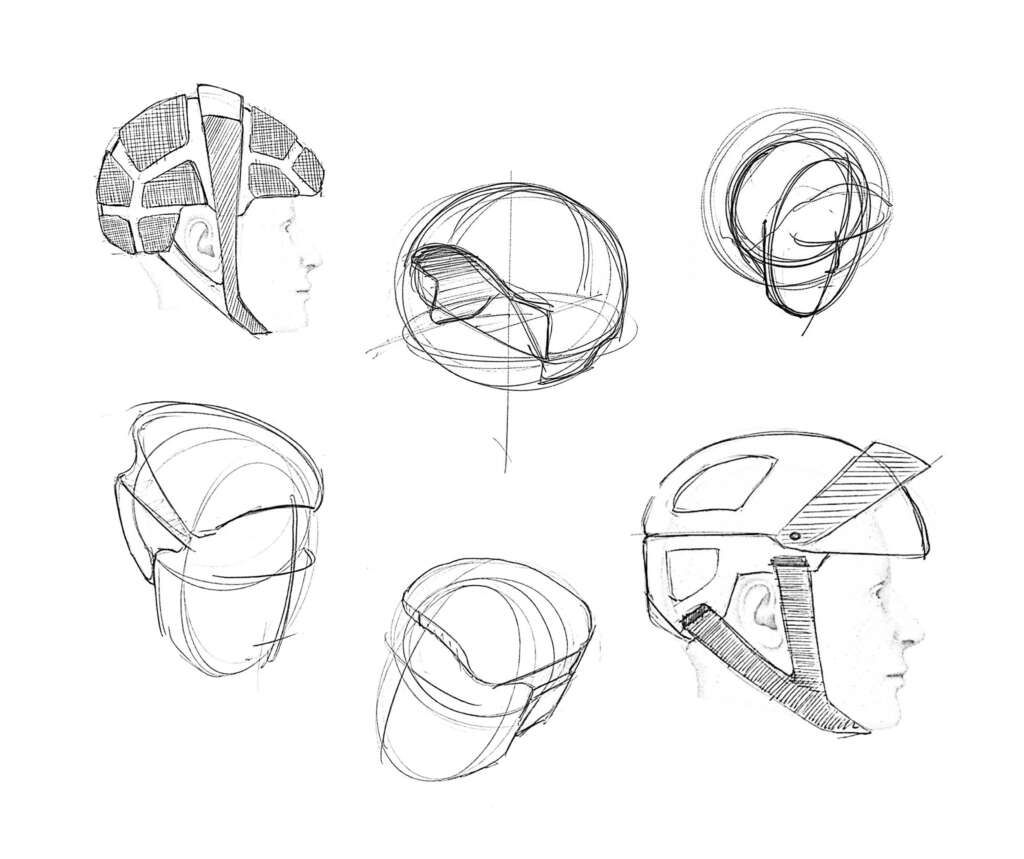

StudioMOM wants to make mobility more sustainable. That is why the MOM-team trains companies in the bicycle industry to adopt circular business practices. The studio also designed sustainable alternatives, such as a transport bike running on hydrogen. A bicycle helmet that is less harmful to the planet felt like a logical next step.

- For the strap and outer shell of MyHelmet hemp textile was used, a biodegradable material to which mycelium attaches itself. The woven structure of the textile also gives the helmet extra strength.

- The different parts grow together firmly. The strap is fixed during the growth process and thereby connects to the other parts at the correct position.

- The production process with mycelium is very different from that with EPS. Therefore, StudioMOM innovatively combined existing techniques to produce the helmet.

- The proof of concept works and can now be developed further.

A considerable step towards bio-manufacturing on an industrial scale

Mars Holwerda, founder and designer at StudioMOM is excited about designer Alessandra Sisti’s work: “By developing a new process, we have taken a considerable step towards using mycelium bio-manufacturing on an industrial scale. The bicycle industry now has something at its disposal to stop the endless stream of harmful, systematic plastic and EPS waste. But we are not there yet.”

StudioMOM is looking for partners to help develop this product further and to bring about real change. “Who is in?”

All photos are courtesy of StudioMOM