Ashen Cabin

Architect: HANNAH, Cornell University Architecture Faculty

Location: New York State, USA

Type: Cabin

Year: 2020

Photographs: Andy Chen, Reuben Chen, HANNAH

Unique design combines previously unusable ash wood, 3D printing, and repurposed automotive robotics to create a template for how future homes could be built.

The following description is courtesy of the architects. The College of Architecture, Art, and Planning at Cornell University announce an important step in their creative and critical response to the Emerald Ash Borer beetle, an invasive species devastating native Ash trees across the country. The Emerald Ash Borer is thought to have been introduced to American forests via human trade and travel in the summer of 2002, and today threatens 8.7 billion trees across the country and nearly one in ten Ash trees in New York state.

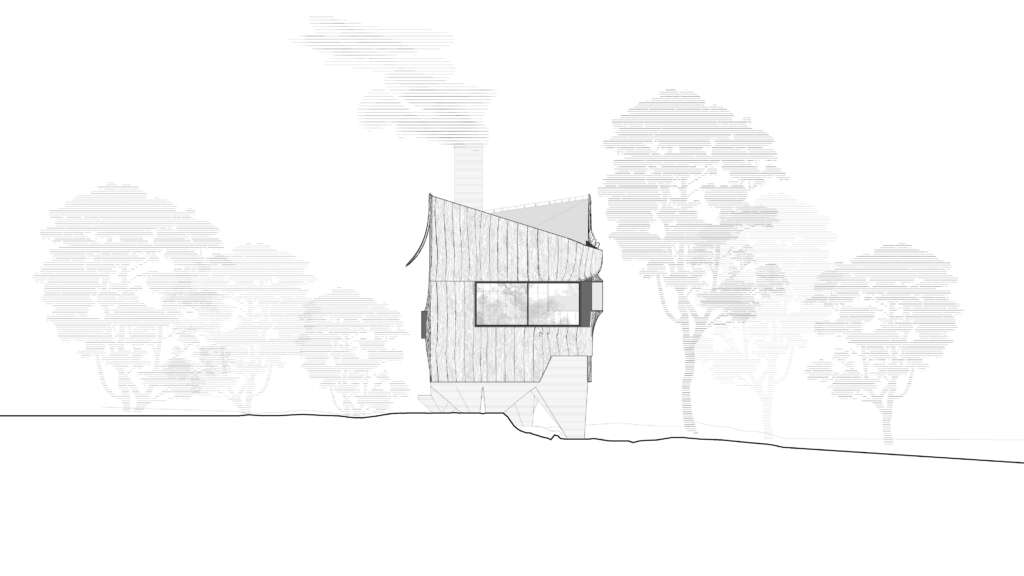

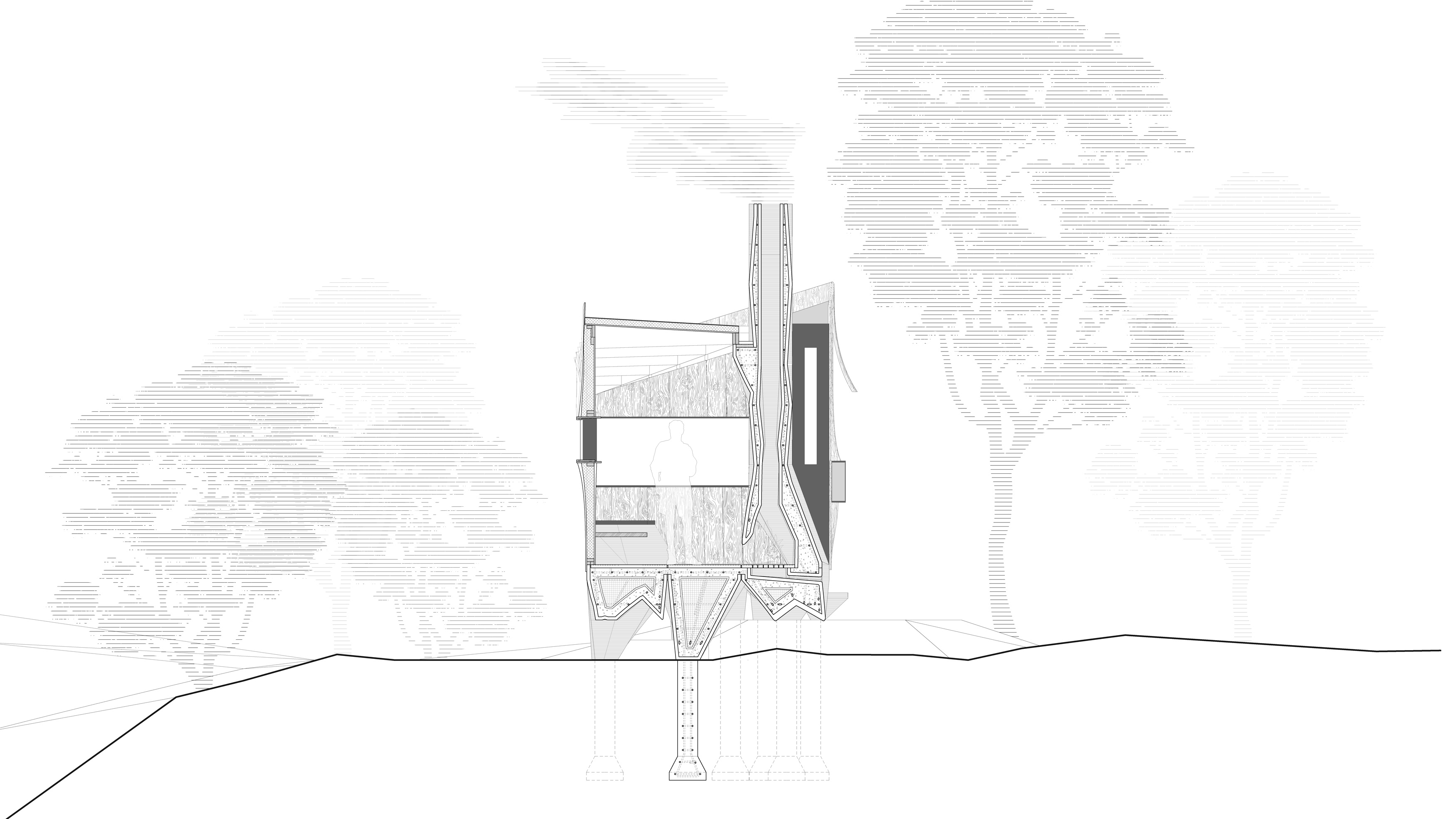

Leslie Lok and Sasa Zivkovic, both assistant professors of architecture at Cornell and co-principals of their design firm, HANNAH, have designed and constructed a full-scale prototype cabin home in rural Upstate New York that responds to the environmental crisis, and, advances the use of technologies such as robotics and 3D printing in timber and concrete construction.

Here is a video showing how the cabin was designed and built

“We believe this prototype offers a new way to think about the future of home construction,” said Lok. “The cabin is a combination of our design research and thinking in response to the urgent condition of our natural environment and possible modes of intervention — and, it demonstrates our potentially replicable use of relatively new technologies that allow us to advance both formal and technological innovation in the [architecture] discipline.”

The Dying Ash Tree, Upcycling a New ‘Waste Material’

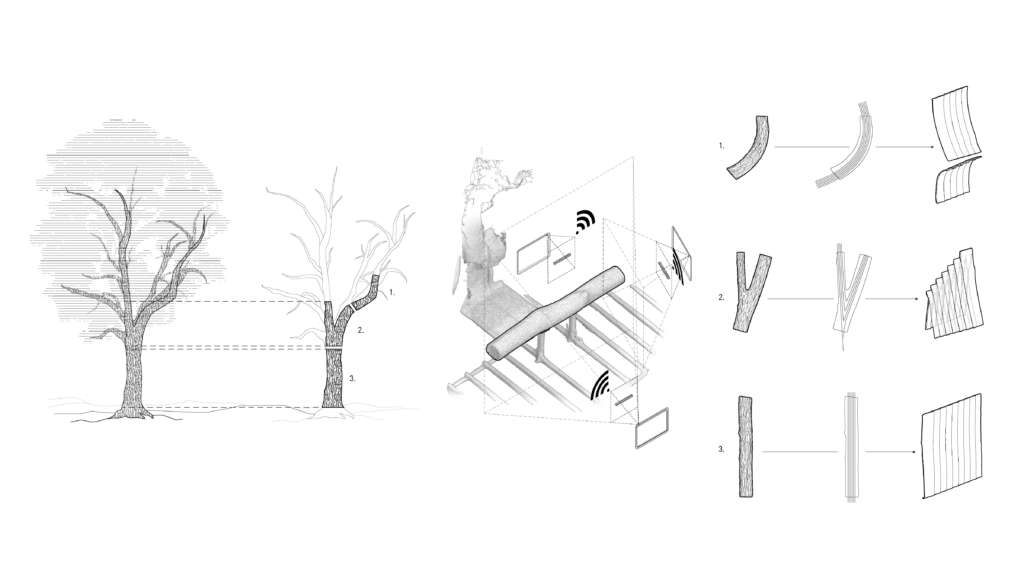

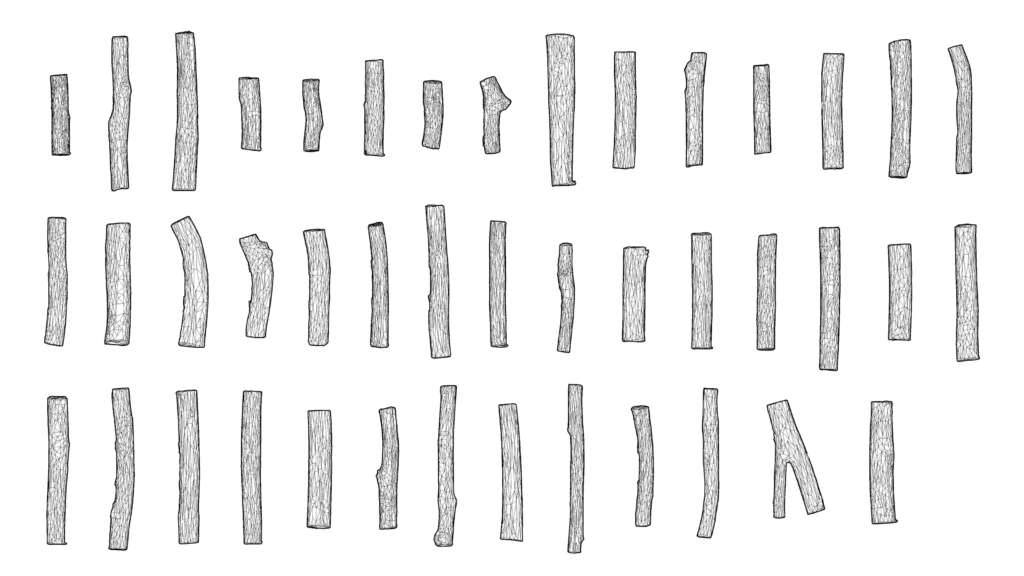

Until recently, mature ash trees compromised by the Ash Borer have not been usable by conventional sawmills as a source of lumber for home construction in part because of their irregular geometries.

“Infested ash trees often either decompose or are burned for energy,” said Zivkovic. “Unfortunately, both scenarios release CO2 into the atmosphere, and so the advantage to using compromised ash for construction is that is that it both binds the carbon to the earth and offsets the harvesting of more commonly used wood species.”

“Infested ash trees are a very specific form of ‘waste material’ and our inability to contain the blight has made them so abundant that we can — and should, develop strategies to use them as a material resource,” he added.

Made Possible by Robotics and 3D-Printed Concrete

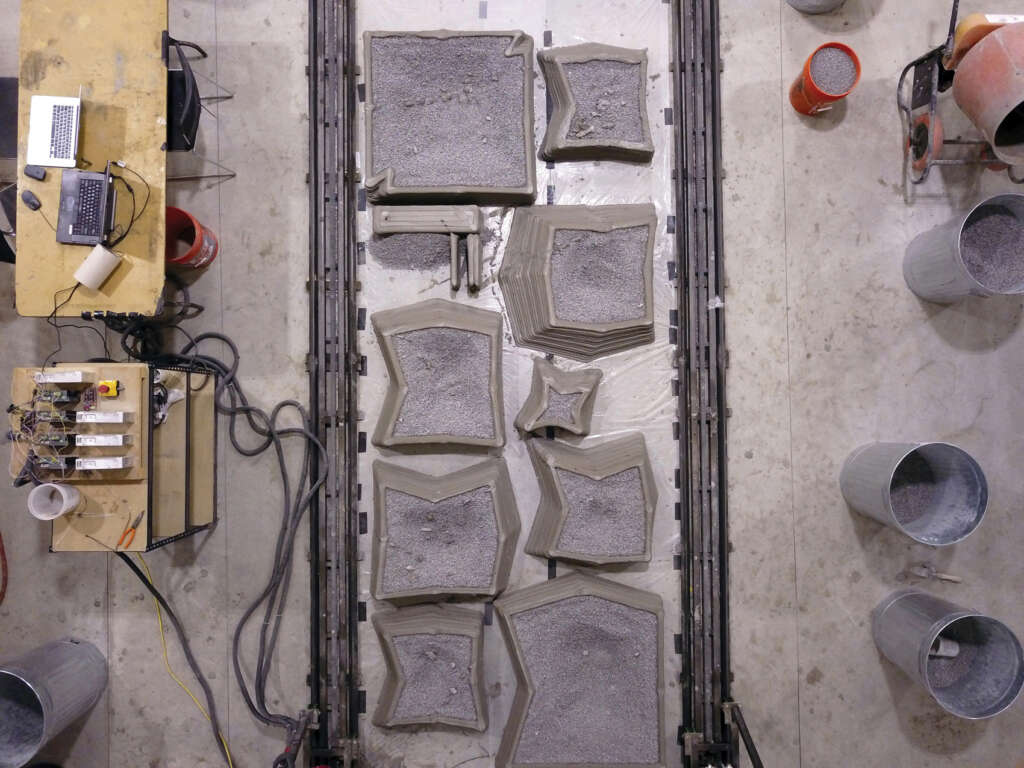

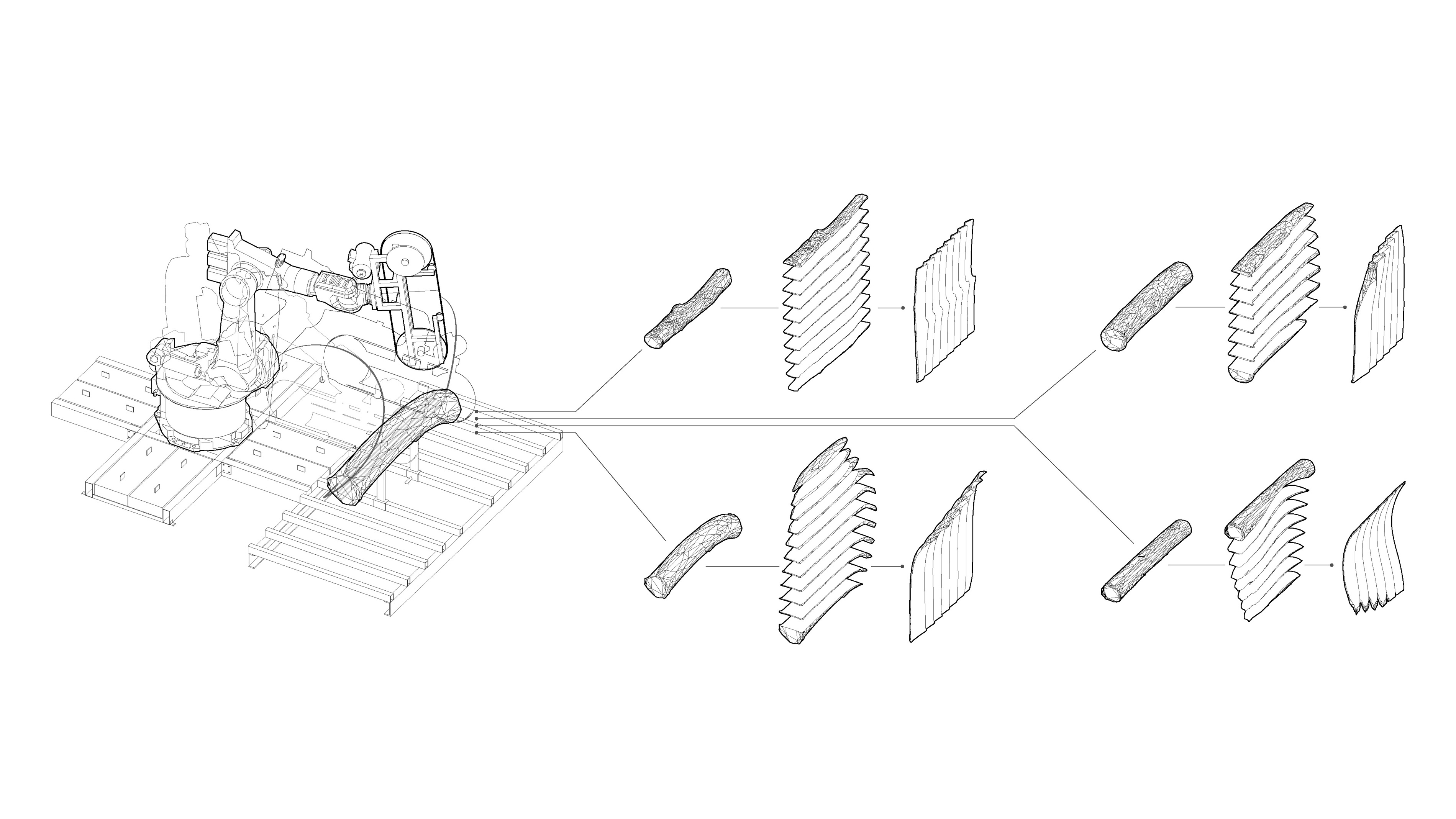

Consistently advancing technologies — specifically robotics and 3D printed concrete — and their use in the architectural design discipline and construction industries make the use of infested ash trees possible. Zivkovic is director of the Robotic Construction Lab (RCL) at Cornell, where the team built a custom robotic platform for the sole purpose of processing the irregular ash trees.

“The team at RCL built the robotic platform specifically for processing irregular ash trees. Basically, we begin by creating 3D scans as a basis for translating and digitizing the complex and irregular geometries of the mature trees. The robot is then programmed to cut and process irregular wood geometries — it is through these current technologies that we can work with this material,” explains Zivkovic.

Robotically cut façade prototype. Credit: HANNAH

Door detail. Credit: Andy Chen

The robotic arm they use was discovered on eBay and previously built cars for General Motors. Zivkovic and the RCL team repurposed the robot, reprogramming it to methodically saw and shape the wood at a scale usable for structural and design elements.

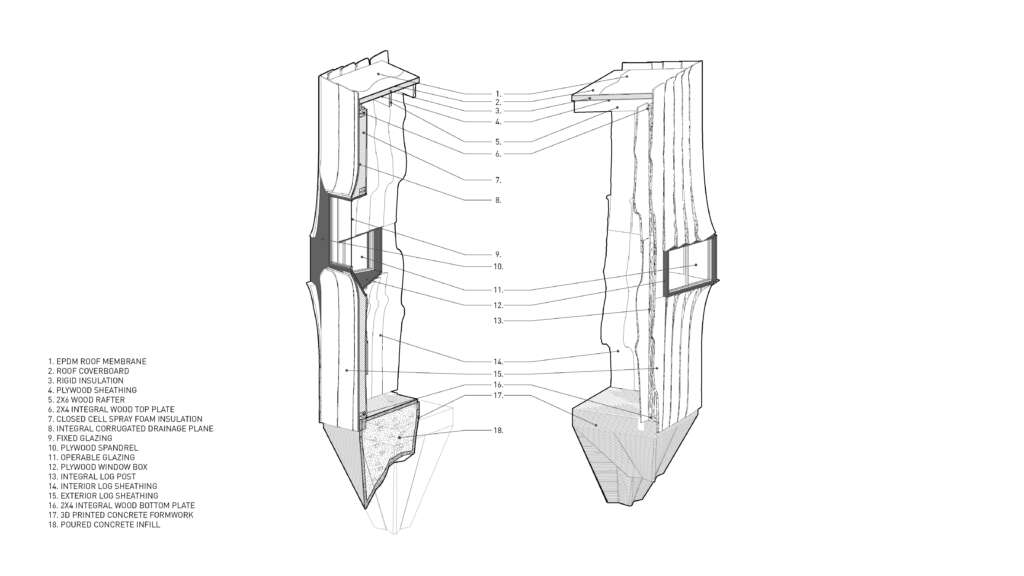

In response to the use of concrete, one of the most widely used building material on earth, the Cornell researchers developed the full-scale 3D printing system that requires no formwork and uses the absolute minimum amount of concrete in the production process. This saves a significant amount of material, significantly improving the CO2 footprint of concrete construction.

“We know that concrete is responsible for 8% of total CO2 emissions,” explains Lok. “By using 3D printing, we eliminate the use of wasteful formwork and can deposit concrete smartly and only where structurally necessary, reducing its use considerably while also maintaining a building’s integrity.”

View of chimney, door, and awning. Credit: Andy Chen

Side elevation of door. Credit: Andy Chen

A Vision for Tomorrow

The cabin demonstrates a new way to think about sustainable housing design, development, and construction in the United States and perhaps beyond. Its inventive design combines two of the most widely used construction materials in the US (concrete and timber), rethinking techniques and approaches for using them from the ground up.

Other industries have benefited enormously from disruptive technologies that make production more efficient and less resource intensive. The residential construction industry, however, has remained unchanged for decades. Lok and Zivkovic’s research and development of a design language informed by the context of the current climate emergency make a strong case for a possible future where architects, engineers, and construction professionals can benefit directly from prototypes that emerge from labs or studios geared for iterative testing, sustained critical thinking, and speculative design.

The project’s combined environmental concern and inventive use of advancing technologies promises to inspire imaginative design, improve material efficiency in construction, reduce long-term construction costs, and increase the availability and versatility of tools for distributed manufacturing that offer unprecedented mass customization to future homeowners.

Project Credits

- HANNAH project leadership: Leslie Lok and Sasa Zivkovic (Principals)

- Project team concrete: Christopher Battaglia, Jeremy Bilotti, Elie Boutros, Reuben Chen, Justin Hazelwood, Mitchie Qiao

- Assembly and documentation team concrete: Alexandre Mecattaf, Ethan Davis, Russell Southard, Dax Simitch Warke, Ramses Gonzales, Wangda Zhu

- Project team wood fabrication and design: Byungchan Ahn, Alexander Terry / Wood studies: Xiaoxue Ma, Alexandre Mecattaf

- Assembly and documentation team wood: Freddo Daneshvaran, Ramses Gonzalez, Jiaying Wei, Jiayi Xing, Xiaohang Yan, Sarah Elizabeth Bujnowski, Eleanor Jane Krause, Todd Petrie, Isabel Lucia Branas Jarque, Xiaoxue Ma

- Representation team: Byungchan Ahn, Kun Bi, Brian Havener, Lingzhe Lu

- Cornell Arnot Teaching and Research Forest: Peter Smallidge (Arnot Forest Director)

- Project realized with scientific support from the Cornell Robotic Construction Laboratory (RCL)

- Sponsors: AAP College of Architecture, Art, and Planning; AAP Department of Architecture; HY-Flex Corporation; Cornell Atkinson Center for a Sustainable Future, Cornell Arnot Teaching and Research Forest

- Special thanks to: Andrea Simitch and Val Warke.