Urbach, Germany

The following description is courtesy of the Institute for Computational Design and Construction, University of Stuttgart. A previous article on the institute’s biomimetic pavilions can be found here.

URBACH TOWER

A unique landmark built from self-shaping wood. Remstal Gartenschau 2019, Urbach, Germany

The Urbach Tower is a unique wood structure. The design of the tower emerges from a new self-shaping process of the curved wood components. This pioneering development constitutes a paradigm shift in timber manufacturing from elaborate and energy-intensive mechanical forming processes that require heavy machinery to a process where the material shapes entirely by itself. This shape change is driven only by the wood’s characteristic shrinking during a decrease of moisture content. Components for the 14 m tall tower are designed and manufactured in a flat state and transform autonomously into the final, programmed curved shapes during industry-standard technical drying. This opens up new and unexpected architectural possibilities for high performance and elegant structures, using sustainable, renewable, and locally sourced building material.

The Urbach Tower constitutes the very first structure worldwide made from self-shaped, building-scale components. It not only showcases this innovative manufacturing approach and resultant novel timber structure; it also intensifies the visitors’ spatial involvement and landscape experience by providing a striking landmark building for the City of Urbach’s contribution to the Remstal Gartenschau 2019.

Material programming and predictability of shape change

In timber construction, moisture typically causes problems with cracking and deformation; hence, moisture changes and stress development must be carefully controlled. In contrast, in this project wood is programed and arranged in a way to utilize this powerful, naturally occurring deformation to trigger a designed self-shaping behavior. In the same way that machines can be programmed to perform different movements, wood parts can be programmed to transform into predetermined shapes when dried.

While methods of bending wood into different shapes for structure and aes- thetics have existed for centuries and have become recognized industrial pro- cesses, they still mostly rely on brute mechanical force for the shaping pro- cess. Similarly, an understanding of how wood deforms due to changes in moisture content is well known in practice and academics. However, a shift in design thinking, as well as new computational simulations for more accurate prediction, now allow us to use this moisture induced swelling and shrinking to design and program specific self-shaping movements at larger and larger scale.

Self-shaping manufacturing at building-scale

The pioneering development of large-scale self-shaping constitutes a paradigm shift in timber manufacturing from elaborate and energy-intensive mechanical forming processes that require heavy machinery to a process where the material shapes entirely by itself. This shape change is only driven by the wood’s characteristic shrinking during a decrease of moisture content. The curved Cross Laminated Timber (CLT) components for the tower’s structure are designed and produced as flat panels that deform autonomously into predicted curved shapes when dried. The 5.0 m x 1.2 m spruce wood bilayers parts are manufactured with a high wood moisture content and specific layups and dried in an industry standard technical drying process. When removed from the drying chamber the parts are precisely curved. The parts are overlapped and laminated together to lock the geometry in place, forming larger curved CLT components with form stable geometry.

Material-specific computational mechanics models have been developed to both design, predict, and optimize the material arrangement required to produce different curvature types and radius. The technology of self-shaping manufacturing for solid timber boards and the rapid adaptability of the process to different curvatures open up new and unexpected architectural possibilities for thin shell wood structures, using a sustainable, renewable, and locally sourced building material. The Urbach Tower is the very first implementation of this technology on building-scale, load-bearing timber parts.

Sustainable wood construction and functional timber cladding

The self-shaping components are made entirely of spruce wood boards sourced regionally from Switzerland. Individual components span up to 15 m with a ra- dius of 2.40 m and a structural thickness of only 90 mm. The components are 5-Axis CNC cut and detailed from half cylinder blanks and pre-assembled into building groups of three components for transport, including water barrier and external wood cladding. With precise curvature and optimal fiber alignment from the manufacturing process, each component is cut in detailed in just 90 minutes of machine time. A custom-made protective cladding layer consisting of glue-laminated larch wood is added on the outside. This also includes the application of a transparent and durable inorganic coating, which protects the wood from UV radiation and fungi attack. Instead of ripping and turning silver-grey when exposed to outdoor weathering, the larch wood will take on an even white color over time.

The entire process chain, from cutting regional logs in the sawmill to the production of the self-shaping panels, the drying process, and final machining and pre-assembly takes place within the same group of companies and at the same location. This not only allows for sustainable and innovative production, but it also shows, how the self-shaping manufacturing can seamlessly integrate in established industrial wood processing and manufacturing workflows.

Thin-shell high-performance timber structure

The Urbach Tower consists of 12 curved components made from cross-laminated timber. The tower’s load-bearing structure exhibits a thickness of 90mm while cantilevering over 14 meters resulting in a span to thickness ration of approximately 160/1. The inherent curvature enables a highly slender and lightweight tower structure of only 38 kg per square meter surface area. In the assembled state, the tower acts as a surface-active structure through its expressive curved geometry. The lightweight building elements are connected by crossing screws, the arrangement and specific angle of which is optimised throughout the structure in relation to their utilization while preserving a continuous connection along the seam for homogeneous load transfers.

The prefabricated assembly groups of the tower, each consisting of three curved components, were assembled in a single working day by a team of four craftsmen without the requirement of extensive scaffolding or formwork, and topped-off by a transparent roof. The structure showcases the possibilities for efficient, economical, ecological and expressive wood architecture that arises at the intersection of master craft, digital innovation, and scientific research.

Unique architectural landmark for the Rems Valley

The Urbach Tower is one of 16 stations designed by some of the most renowned German architects for the Remstal Gartenschau 2019. The stations are small, permanent buildings that evoke the traditional white chapels distrib- uted in the fields and vineyards along the scenic Rems Valley. Located on a prominent hillside in the center of the valley, the 14 m tall tower is a striking landmark that visually connects several stations. It provides a place of shelter, internal reflection, and outward view by revealing stunning vistas and framing the landscape. The distinctive form of the tower constitutes a truly contemporary architectural expression of the traditional construction material wood. It celebrates the innate and natural characteristics of self-shaped wood in its upwards spiraling shape.

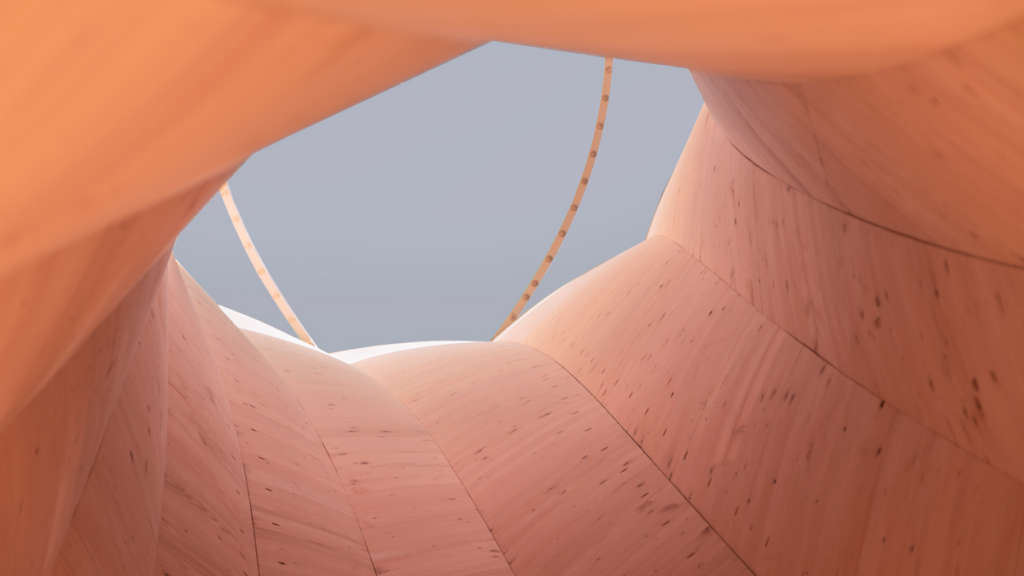

The concave curvature of the structure on the outside results in sharp lines and crisp surfaces, which is further accentuated by direct daylight and whitening of the larch cladding over time. In contrast, on the interior the convex curvature creates an unexpected visual and tactile material experience, with the timber structure appearing to be almost soft and textile-like, highlighted by the light washing the gently undulating surfaces. Opposite the entrance, the thin wood envelope opens like a curtain, putting the Rems Valley on center stage.

URBACH TOWER Project Team

ICD – Institute for Computational Design and Construction, University of Stuttgart Prof. Achim Menges, Dylan Wood Architectural Design Self-forming Curved Wooden Components Research and Development

ITKE – Institute of Building Structures and Structural Design, University of Stuttgart Prof. Jan Knippers, Lotte Aldinger, Simon Bechert Structural Design and Engineering

Scientific collaboration:

Laboratory of Cellulose and Wood Materials, Empa (Swiss Federal Laboratories for Materials Science and Technology), Switzerland & Wood Materials Science, ETH Zurich (Swiss Federal Institute of Technology Zurich) Dr. Markus Rüggeberg, Philippe Grönquist, Prof. Ingo Burgert Self-forming Curved Wooden Components Research and Development (PI)

Industry collaboration:

Blumer-Lehmann AG, Gossau, Switzerland Katharina Lehmann, David Riggenbach Self-forming Curved Wooden Components Research and Development, Wood Manufacturing and Construction

URBACH TOWER Project Support

Gemeinde Urbach

Remstal Gartenschau 2019 GmbH

German Federal Environmental Foundation Design, Fabrication and Engineering Methods for the application of curved wood elements in high-performance, resource-efficient wood construction: Project Tower Urbach, Remstal Gartenschau 2019

Innosuisse – Swiss Innovation Agency Smart, Innovative Manufacturing of Curved Wooden Components for Architecture with Complex Geometry

Carlisle Construction Materials GmbH

Scanntronik Mugrauer GmbH

URBACH TOWER Project Data

Dimensions

• 14.20 m tall timber structure

• 4.0 m radius bottom, 3.0m radius top, 1.6m radius middle

• Spruce Wood CLT with 10-30-10-30-10 build up

• Larche Wood façade with titanium oxide surface treatment

• 5 axis CNC cut components

• 12 individual prefabricated components pre-assembled in groups of 3

• Crossing screw connection detail with wood alignment blocks

• 8 Sensors to monitor internal WMC of the structure

Construction System Curved surface active tower structure, self-shaped curved cross laminated spruce timber (CLT) 10 -30-10-30-10 layup, glue laminated Larch façade with ti- tanium oxide UV protection surface treatment, curved polycarbonate roof with steel support structure.

URBACH TOWER Quotes Project Partners

Prof. Achim Menges, Dylan Wood ICD – Institute for Computational Design and Construction

“Computational design and simulation enables us to work with the material and to unfold specific form from it, rather than forcing it into shape.”

“Wood can be programmed to take a specific shape. While making this work is relatively simple, predicting the outcome is the real challenge. Being able to do so opens up many new architectural possibilities.”

“The self-shaping manufacturing technology highlights how advanced understand and computational models of even the most well-known materials can lead to innovative and sustainable building processes.”

Prof. Jan Knippers, Lotte Aldinger, Simon Bechert ITKE – Institute of Building Structures and Structural Design

“The structure is more than 14 m high, only 9 cm thick and with no visible details: What looks simple is difficult to achieve and only possible through an ingenious interplay of form and force.”

URBACH TOWER Quotes Project Partners

Dr. Markus Rüggeberg, Philippe Grönquist, Prof. Ingo Burgert Laboratory of Cellulose and Wood Materials, Empa (Swiss Federal Laboratories for Materials Science and Technology)

“We are proud to have developed the world’s largest self-shaping elements, by an elaborate use of sustainable material wood. The unique tower design highlights the complex shapes enabled by this new manufacturing principle.”

“The ability to predict and even design the shape-shifting patterns in large wood bilayers opens entirely new application of wood as a building material, ranging from self-shaping entire building components to meter sizes high stiffness passive actuators for building facades, all with a highly sustainable natural material.”

Katharina Lehmann, David Riggenbach Lehmann Group / Blumer Lehmann AG

“The project is an outstanding example of the interaction between technology, research, architectural ambitions as well as practical skills and know how. From an industry perspective, the self-shaping manufacturing highlights the incredible intelligence of wood as a material. It is always surprising to see there is more to learn from a material we have worked with for generations.”

“The research in shelf-shaping manufacturing adds an entirely new dimension to timber! While we consider ourselves experts in timber construction, taking on innovative projects like this are inspiring and at the same time show us there are endless potentials for wood as building material”.

“While machining and processing are a cornerstone of the wood industry, the self-shaping technology highlights how advanced knowledge and understanding of the material can lead to truly inspiring timber architecture.”